Expertise

Process

AFF Groupe’s know-how and experience have been recognized for many years.

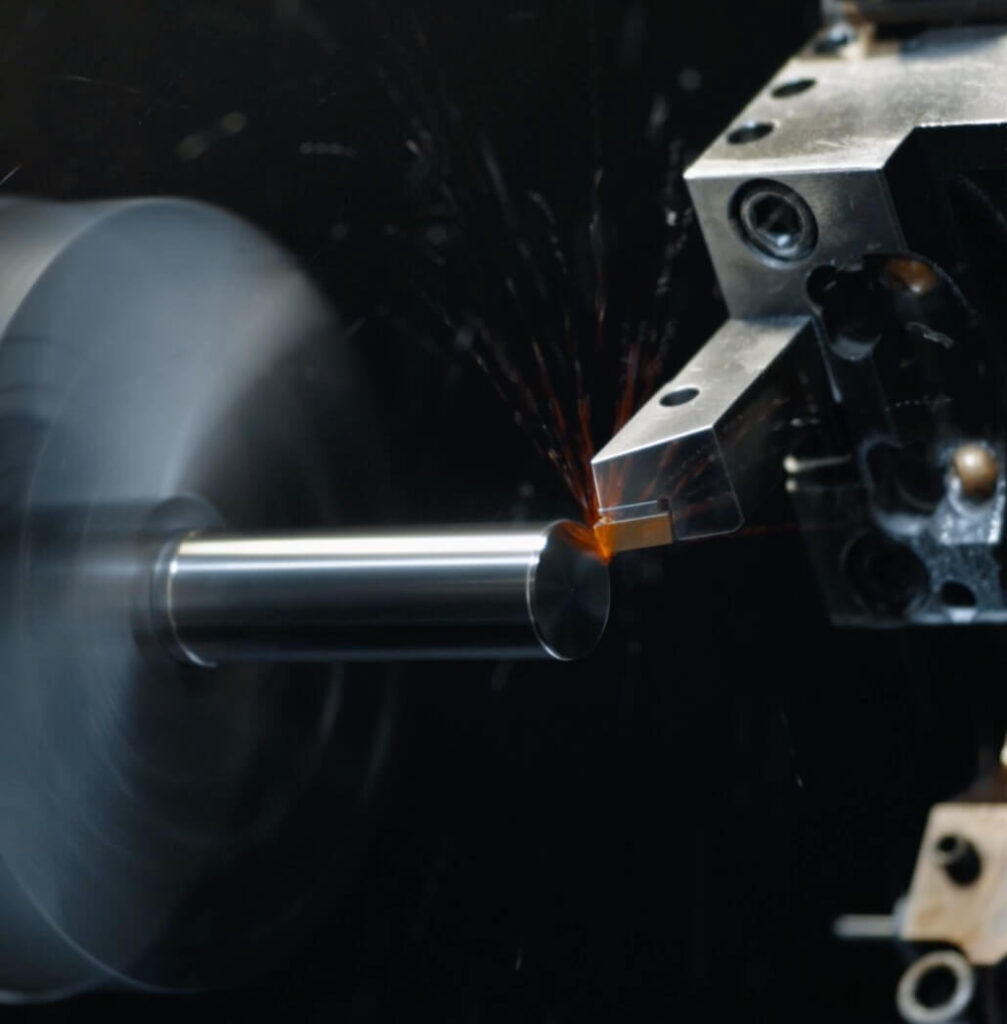

Our core business is cold heading, but we attach real importance to the integration of the entire value chain of our business. This is essential to ensure the mastery of each step of the manufacturing process.

Innovation / R&D

The skills and synergies of the 4 production plants are united to analyze the needs of each customer and ensure the production of high quality and efficient parts.

We put our know-how at the disposal of our customers to best define the part that will meet their functional and economic needs.

The resistance, the material, the mechanical characteristic, the dimension, the shape or the function of destination are all parameters studied and cross-checked by us to optimize each part.

AFF Groupe uses powerful deformation simulation software (part and tool).

A fantastic solution for designing the right components the first time, reducing large-scale testing, reducing material and energy costs, extending die life, shortening the design phase and reducing lead times marketing.

We also offer the study of the transfer of machined parts to their manufacture either completely by cold heading, or by cold heading with a reworking.

Operational effectiveness

Operational Excellence is an attitude that we develop on a daily basis in our teams.

Our approach is centered on the involvement of our employees focused on serving our customers.

Continuous improvement focuses on problem solving at the workstation to improve standards that allow production to constantly improve performance in terms of safety, quality, lead time and productivity.

We promote collective work with our management rituals (synchronized agendas for production, project and problem solving meetings).

The expertise of our teams’ Lean tools (5S, SMED, VSM, TPM, QRQC, 5WHY, OHP, TRS, etc.) are pooled through exchanges between sites when carrying out improvement projects that allow sharing of good practices.